Frequently Asked Questions (FAQ)

What certifications do you have?

We are certified under ITAR (International Traffic in Arms Regulations) and are currently in the process of attaining an ISO 9001:2015 certification.

What materials can you cut?

We can cut most materials, except for tempered glass and porcelain. By city ordinance, we cannot cut lead, depleted uranium, or any material that may pose a risk to the city’s water supply. Medium-density fiberboard (MDF) can be cut, but it absorbs water, making the waterjet less effective for this material. Our laser can only cut conductive materials (metal), and cannot cut rubber, plastic, or wood. We can cut glass, but we cannot pierce the inside of a sheet to make interior cuts. All glass cuts are made from the edge of the sheet to minimize the risk of shattering. Please note that stress from cutting glass may cause it to shatter occasionally, so we recommend providing extra pieces as a precaution.

What machines do you have and how big of a sheet can you cut?

- 4000W fiber laser with a bed size of 240″ x 96″

- Omax Tilt-A-Jet waterjet with a max bed size of 162″ x 75″

- 150w CO2 Laser with a bed size of 63″ x 40″

What tolerances can you hold?

We can hold tolerances of +/- 0.005″ on both the waterjet and laser. For materials thicker than 0.5″, the tolerance is +/- 0.01″ or more, depending on the thickness.

Do your machines compensate for the angle of the cut?

Yes, the Omax Tilt-A-Jet head compensates for the taper angle of the cut on materials that are 0.25″ thick or more. The laser does not have this capability.

Can you give me a ballpark price if I describe my part or send a picture?

Unfortunately, we cannot provide a ballpark price. Prices are determined by entering a CAD file into the system, where the price is generated based on the file.

Will it cost less if I order a higher quantity of parts?

Yes, discounts are based on run time, so the longer the cut, the greater the discount. Let us know the quantities you’re interested in, and we will provide quotes at different price points.

What is the maximum tilt you can do on the waterjet?

The waterjet can tilt up to 7 degrees from vertical.

Can you do a rush job?

Yes, we offer rush services. Please call us at 970-395-1010 or email us HERE for rates and rush scheduling.

How thick can you cut?

- 6″ on the waterjet

- 0.5″ carbon steel on the laser

- 0.25″ stainless steel and aluminum on the laser

Can I provide my own material?

Absolutely! You can bring us the material, or have it delivered or shipped to us.

Are different cut qualities available for different areas of my part?

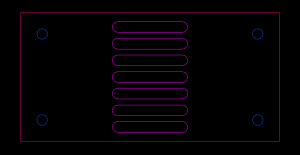

Yes, for waterjet cutting, we offer various quality levels. HERE is a visual example showing various features can be cut at a different quality:

- Standard cut quality is “Quality 2,” which produces good edges.

- For aluminum, we use “Quality 3.”

- “Quality 5” is the highest quality cut, but it increases cutting time and cost. We can provide quotes for various cut qualities.

What drawing format do you prefer?

We accept the following formats:

- DXF (preferred)

- DWG

- AI

- STEP or STP (must be flattened if it’s a bend file)

- If you don’t have a CAD file, you can bring the part in, and we’ll measure and cut a new one for you. If all you have is a “napkin” drawing or a cardboard cutout, we can create a CAD file for you.

To ensure the scale is correct, please include a 1″ x 1″ box or a PDF with dimensions. Since our CAD program doesn’t specify metric or English units, any indication of units on the drawing is helpful.

We cannot open SLDPRT or SLDDRW files, which are SolidWorks files.

Can you deliver?

Yes, we deliver mainly to the Northern Colorado region, Metro area of Denver, and Cheyenne. Delivery fee varies depending on location.

Do you ship?

Yes, we can ship your parts. If the item is too large or heavy for regular shipping, we can arrange freight delivery.

When should I choose the waterjet instead of the laser?

- If more than 50% of the material is being removed, the part is likely to warp (typically medium sized parts or larger).

- If you’re tapping or countersinking many holes, using the laser could damage post machining bits/tooling.

- If the material exceeds the laser’s maximum thickness (0.5″ for steel, 0.25″ for stainless steel and aluminum), it will be waterjet cut.

Do you do bending or other machining work?

We can countersink and tap parts in-house. For bending, welding, powder coating, and other machining services, we work with trusted local shops to complete your parts.

How do you prevent materials like carbon fiber from delaminating?

We pre-drill holes before waterjet piercing to help prevent delamination.

What is the smallest feature you can cut?

The waterjet has a precision kerf of 0.03 inches, meaning that for thin materials, the smallest slit or dot piercing it can create is approximately this width. As the material thickness increases, the kerf expands causing the slit to gradually widen toward the bottom of the cut. This variation in width occurs due to the water stream as it moves through thicker material, resulting in a larger taper at the base of the cut.

Can you put part numbers into parts with the waterjet or laser?

• For the waterjet, the material must be at least 0.125″ thick.

• For the laser, the sheet must be at least 16 gauge.

• The recommended text size for etching is at least 0.5″ tall.

Here are sample photos:

Waterjet Example

Laser Example

Laser Example

CO2 Cermark marking

Can you etch with the waterjet or laser?

No, we can scribe which is a surface marking.

Waterjet Example

Laser Example

Laser Example

Depth of the scribe cannot be defined.